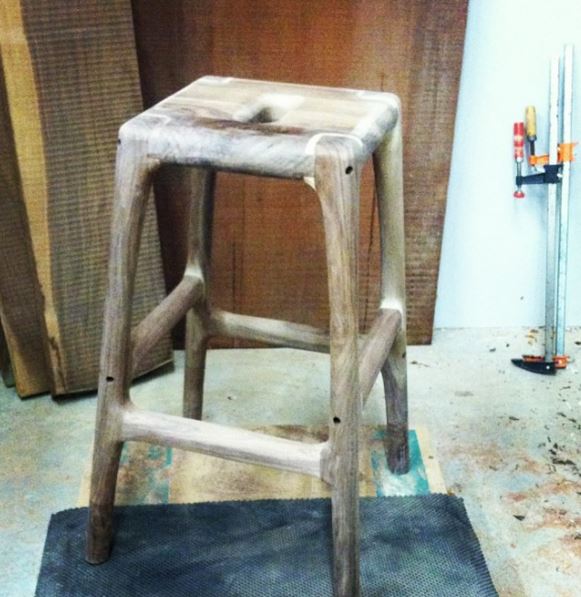

One evening while working on a piece of furniture. I wanted to sit down to take a brake but I could not find a seat to sit in. As I stood there looking around, thinking to myself, how can I not have a chair or a stool to sit on in my shop. I thought, why not design something just for the shop, a "shop stool". That night I started thinking about what I want in a shop stool. A stool with arms or no arms, a back or no back and how would I use this around the shop. I didn't want arms because I am always moving in and out, up and down and I thought they would get in the way. I didn't really want a back either. I didn't want a front or a back so i could sit on it from every side. I wanted something simple but nice and sturdy that could withstand a beating and be used daily. I ended up coming up with my square stool, it is simple but elegant. I started my rough sketches and worked to scaled drawing of the stool. I really liked it so I went ahead and drew a full size sketch on the back of a piece of drywall I had around the shop. The next day we had to finish hanging dry wall on the back wall. Of course that piece of drywall, with my full size drawing, was the first one up. Once we finished the drywall I was able to start working on the shop stool again. As I looked around the shop for my full size drawing, I realized that I screwed it to the wall. Having to draw it again this time i drew it on a piece of plywood. Once I had everything I needed to get started I was able to figure out how much wood I needed. I started making one from walnut and one from elm.

I started with the seat. I cut out my joinery and moved onto the legs. Once I had the legs on, I started to realize how much I am going to use this not only has a stool but as a saw horse. I was clamping stuff to the top of the seat to hold it in place as I worked on other projects. while moving the stool around the shop I thought a handle in the center would be great. Once I added the handle I could finish shaping and start sanding.

At this point all I have left is shaping and sanding.

I love this stool and use every time I am in the shop.